By Tricia Brown

University of Iowa Strategic Communications

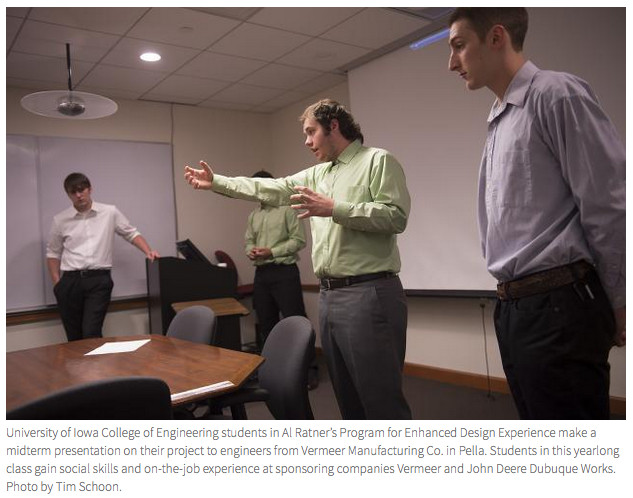

Students in Professor Al Ratner’s Program for Enhanced Design Experience (IE:4600:0001/ME:4086:0002) class don’t just solve engineering

As a result, this highly selective class often leads to job offers at graduation.

“The thing I try to have the students learn is not technical. The goal of this class is not that,” says Ratner, professor of mechanical and industrial engineering. “My goals are purely social.”

The class, called PEDE, is a highly competitive, two-semester course in which students in the University of Iowa College of Engineering are chosen by business sponsors seeking help with engineering problems. John Deere Dubuque Works has been the primary sponsor since the class’ inception in 1994.

This semester, about 65 students applied and 16 were chosen—12 are working on three projects for Deere and four are working on a project for Vermeer Manufacturing Co. in Pella.

In addition to working on the specific projects—such as improving the serviceability of doors for a piece of machinery called a "feller buncher," which is used in the logging industry, or redesigning a built-in tool box for a backhoe—PEDE students also work for and are paid by the company for one week each semester.

Victoria Trojanowski, 21, a senior mechanical engineering major from Bellevue, Nebraska, said she applied to be in the class because she thought it would be a unique learning experience.

“Since it’s a year long, it seemed like a good idea to get real-world experience,” she says. “I’m learning how our engineering knowledge transfers to a real-world environment.”

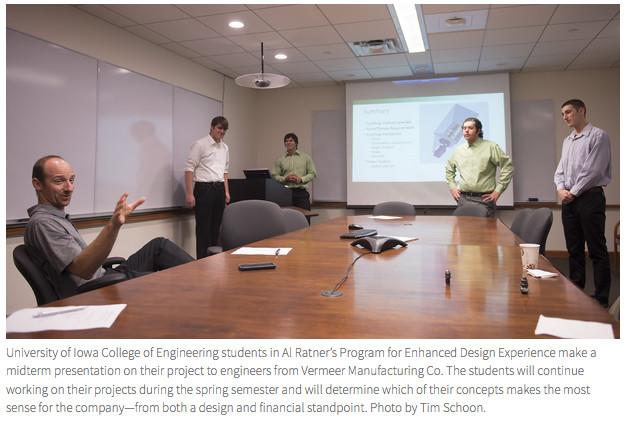

The 20-minute presentations covered research the students had done, such as talking to customers and dealers about changes they’d like to see, and investigating features on products manufactured by competing companies. The groups also created several conceptual design options to present to the engineers and talked about the pros and cons of each.

George Grigalashuili, 21, a senior mechanical engineering major from the Republic of Georgia, says he especially liked Jumpstart Week, the week in August that the students spent working for their respective companies.

“I’ve only worked at one company in my life,” he says. “It definitely opened my eyes to different fields of engineering I could go into.”

For about half of PEDE students, a successful class project leads to something else: a full-time job after graduation. Deere & Co. hires about 50 percent of the students it works with, Ratner says.

The students will continue working on their projects during the spring semester and will determine which of their concepts makes the most sense for the company—from both a design and financial standpoint. In May, they will meet with the engineers again and show them a prototype they will have manufactured.

Ratner says this class takes students a step beyond their technical training.

“They need experience working as an engineer,” he says. “Plus, it’s a lot of fun. And I think we deliver good value for the companies.”