Main navigation

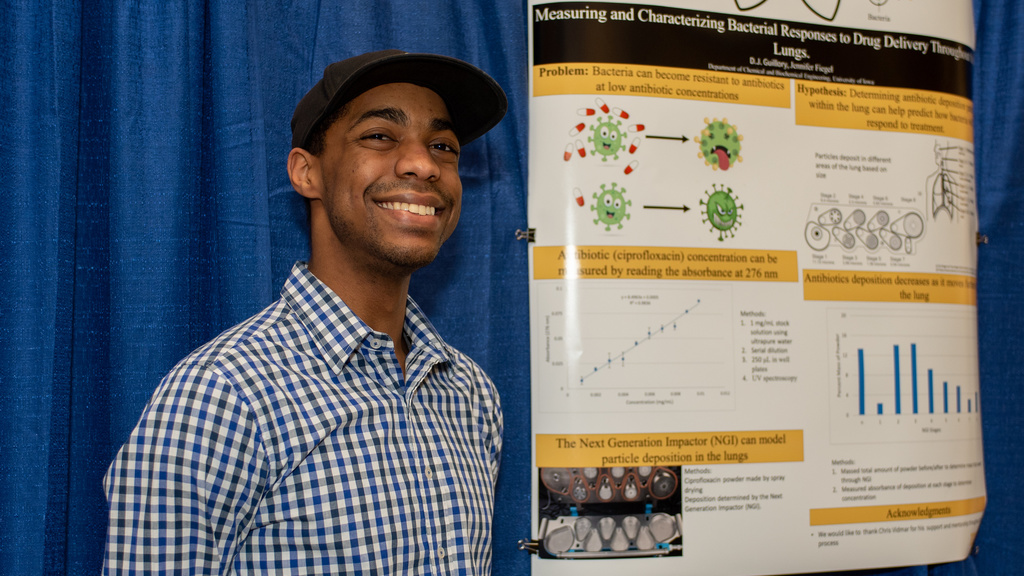

The University of Iowa Department of Chemical and Biochemical Engineering offers both thesis and non-thesis Master's of Science programs, a Doctor of Philosophy program, and a five-year U2G program. Graduate students in the Department of Chemical and Biochemical Engineering gain an understanding of the principles of engineering science, with a focus on a chosen research area.

Information for Graduate Students

Student Learning Outcomes

MS

Graduates will:

- Demonstrate a mastery of core chemical engineering concepts;

- Effectively communicate scientific concepts and/or research results in both written and oral formats to scientific and general audiences;

- Demonstrate knowledge of and commitment to safe and ethical behavior through adherence to best safety practices and academic integrity principles.

- Students completing the program with thesis will additionally demonstrate the abilities to:

- Demonstrate the ability to perform independent research, critically identify and solve research problems, summarize disciplinary information, evaluate research findings.

PhD

Graduates will:

- Demonstrate a mastery of core chemical engineering concepts;

- effectively communicate scientific concepts and/or research results in both written and oral formats to scientific and general audiences;

- Demonstrate the ability to perform independent research, critically identify and solve research problems, summarize disciplinary information, evaluate research findings;

- Demonstrate knowledge of and commitment to safe and ethical behavior through adherence to best safety practices and academic integrity principles.

Contacts

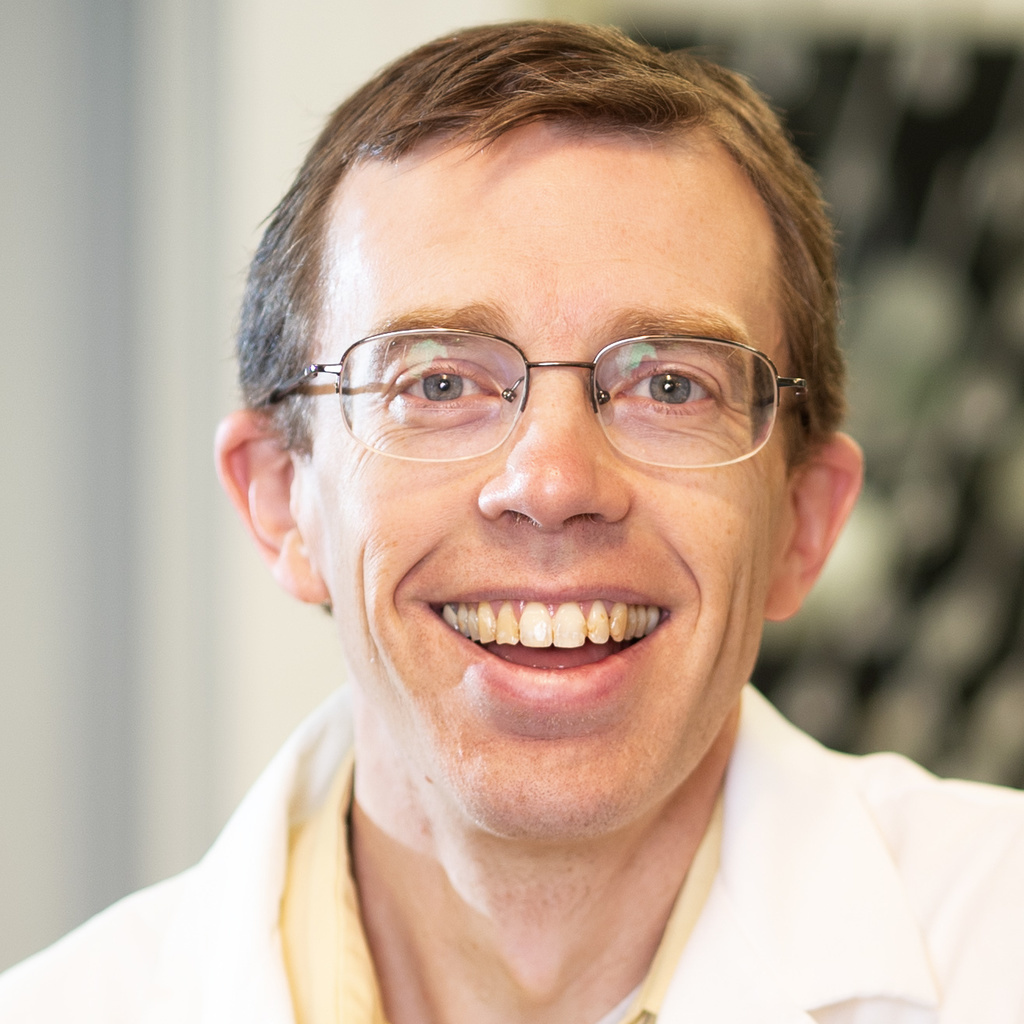

Eric Nuxoll

Associate Professor, Chemical and Biochemical Engineering

The director of graduate admissions recruits and serves as the first point of contact for prospective graduate students.

Alec Scranton

Professor, Chemical and Biochemical Engineering

The director of graduate studies is an advocate for graduate students and their success. He advises incoming students, coordinates the research advisor selection process, monitors and tracks student progress, and is a point of contact for graduate program questions.

Jun Wang

Lichtenberger Family Chair in Chemical and Biochemical Engineering

The departmental executive officer is the academic administrator the Department of Chemical and Biochemical Engineering.

Sara Hartman

The graduate program specialist is a contact for prospective, incoming, and current students for anything related to the academic program.

Amanda Jensen

The department administrator is a point of contact for anything related to graduate student human resources, finance, travel, and administrative odds and ends.

News Highlights

Internships and co-ops are shaping Iowa engineering students

Iowa PhD student's algorithm becomes global resource through industry partnership